Case Study

Robust and reliable solution for the Japanese largest car manufacturer

Highlights

Japanese company formed as a joint venture between the largest car manufacturer and a leading electronics company to manufacture batteries for Electric Vehicles (EVs) and Hybrid vehicles.

The company approached Software Imaging to mature the PoC into a scalable, Industry 4.0 capable solution.

Overview

Company had a prototype Image Analysis solution developed by an IT research division of the car manufacturer, which was to take pictures of internal components and then use a trained ML (machine learning) model for anomaly detection and identify any quality issues.

The system replaced a manual process, which was resource intensive and viewed as inaccurate with a high margin of error. Once installed into a vehicle, replacing or repairing EV batteries is expensive due to both the cost of the replacement components and the cost of labour.

Once the technology of the QA process was proven, the intention of the project was to develop the PoC into a production system.

The Challenge

- The PoC was proven on limited test data, rather than real production data from the end-to-end QA cycle.

- The production solution required several integration points with external systems and hardware.

- The relationship between the various parties had become fractured and it was difficult to progress the project.

The biggest challenge was that the PoC was not a production ready solution. Typically, a production environment in manufacturing runs 24×7 and have an expected lifespan of many years. Several improvement areas were identified to ‘productize’ the PoC, including:

- Additional features, including new functionality and integration.

- Resolve a number of memory leaks

- Increase performance

- Expand both execution and error reporting

- A high degree of resilience

- Can be easy maintained

The Solution

Software Imaging were introduced to the company by their Japanese group company, Synapse Innovation. From the outset, it was possible to establish an excellent relationship with the customer and best approach to mature the PoC into a scalable, Industry 4.0 capable solution was identified.

Solution Details:

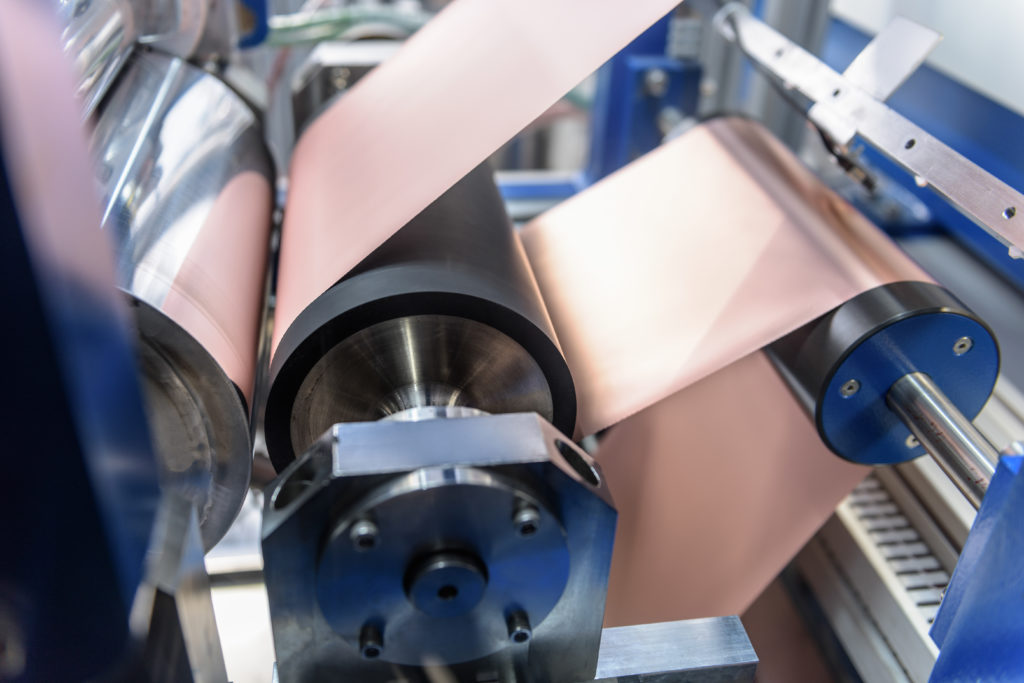

The anomaly detection solution is for the QA of EV and hybrid batteries prior to them being sealed and shipped to the car manufacturing locations.

- Programmable Logic Controllers (PLCs) control several cameras which each take several images.

Each cycle, from start to finish had to be completed in less than 4.6 seconds, which matched the time frames of the battery production.

A Production Capable Solution:

The PoC confirmed that a AI/ML driven solution for image QA was feasible for the customer’s user case. To ‘productize’ the PoC, several improvement steps were taken:

- Additional features and functionality, such as integration, logging and reporting were added.

- The overall program was rearchitected to implement, multi-threaded, parallel processing which vastly increased scalability.

- Particular attention was paid to software resilience, to ensure the overall QA process can continually execute.

Anomaly detection and model training were separated into 2 separate programs, to improve readability & maintainability - reduce unnecessary processing - improved code re-use.

- Significant memory leaks were identified and resolved, and the overall memory management was optimized to maximize throughput.

- The program was structured so it could utilize a GPU (graphical processing unit) if available.

- The existing code was refactored to implement several improvements:

- The code was enhanced to increase readability and maintainability.

- Unnecessary processing was removed

- Code reuse and similar best practices were implemented

- (self)documentation to make the code easier to maintain in the future.

Integration was a key requisite to enable a robust and reliable solution. Rest APIs were used to integrate, which met all requirements, including the important cycle times.

The requirement to display the most recent results on the server console was a late breaking requirement. Thankfully, due to a well architected design, it was a straightforward task. The coherent state management was really the thing that made this easy - i.e. design.

The same web server used by the RestAPIs for integration was also used to display the testing results, and refresh with each the completion of the next cycle.

Development to a Production System:

Development and testing activities were carried out on the cloud, although it was known from the beginning that the final deployment would be on-premises, which tends to be a standard approach for mission critical manufacturing systems.

Development was an iterative process, which enabled a prompt response to feedback. For example, during the project there were some changes to how the cameras were controlled by the PLCs. Careful design and management enabled changes to be managed with flexible design. This reduced the testing burden of the deployed system, therefore enabling it to be bought online and into the manufacturing process quickly, effectively and with no impact to the manufacturing process.

The Result

Feedback from the customer has been very positive. The technical capabilities of Software Imaging coupled with their knowledge in the manufacturing sector enabled the delivery of an integrated anomaly detection solution. The customer viewed this as a unique achievement.

Next steps:

A number of future projects have been identified, the first, another ML driven QA solution is underway. The new project is to inspect the quality of welding, but rather than using images, will integrate to IIoT (Industrial Internet of Things) devices and use 3d mapping to identify defects.